Stormwater Piping; Affects During and after Construction

What is Stormwater Piping and How can it Affect a Construction Site?

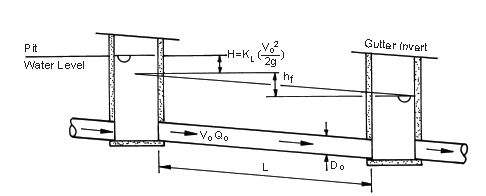

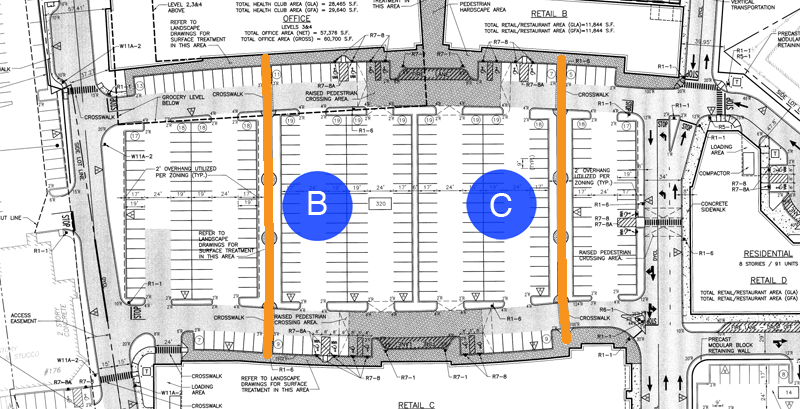

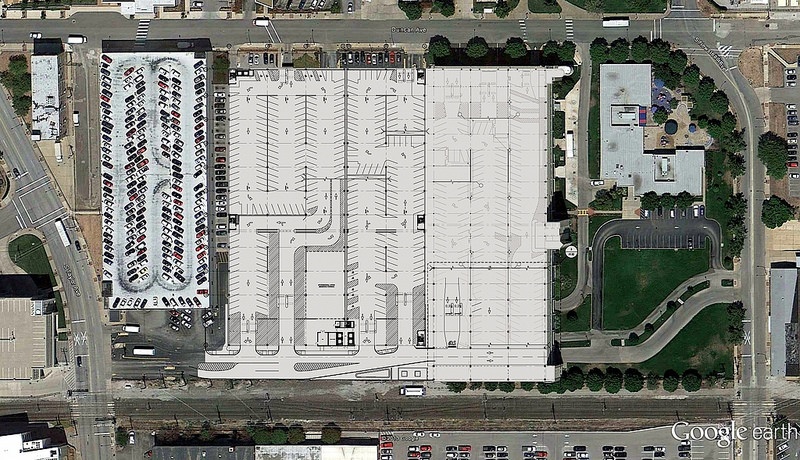

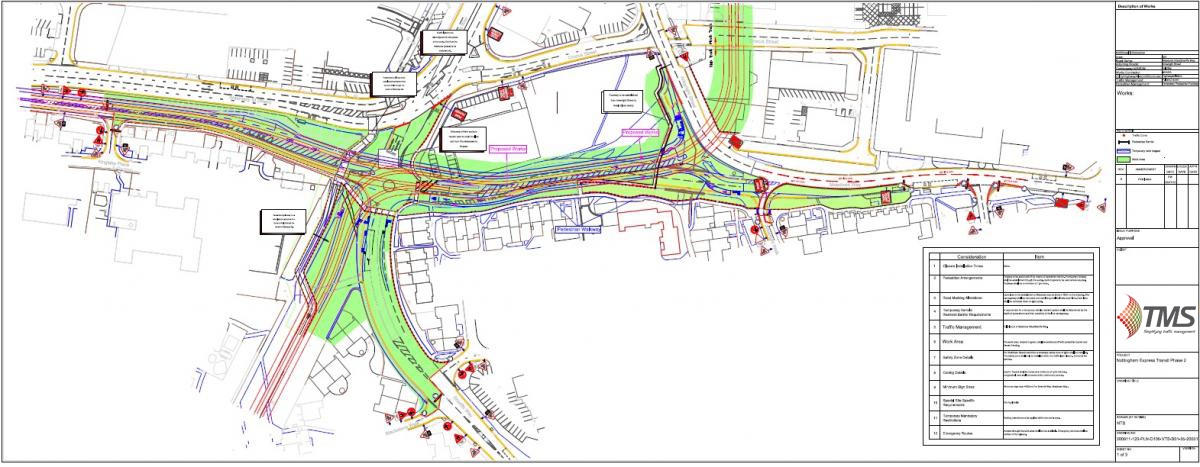

Most storm sewer piping and stormwater piping flows by gravity, no pumps create pressure. The storm water drops into the system by inlets or roof drains then flows downhill. Obviously, the grade of the pipe matters. A low spot, or belly, in the pipe makes a trap, while a high spot, or hump, creates a dam. So the pipe crew needs to keep the pipe inverts (the lowest spot in the pipe where the water flows) installed in a straight line, at the slope required on the site drawings.

While the storm sewer piping rarely appears on the critical path of a project schedule, it’s surprising how many times the storm sewer installation becomes a problem and delays a project. Some of the common issues that occur with storm sewer piping are:

- Unexpected rock or obstacle excavation.

- Existing pipes in the way, discovered only during the installation.

- Design errors that only become apparent during the installation.

Because of these type problems, a company like Nationwide Consulting, LLC can head off problems that may arise in the site development process and pay special attention to the storm piping and other underground infrastructure. The goal for the pipe work should be a speedy installation that surpasses the specification requirements (i.e. leakage, line, grade, backfill, etc.). Even if the pipe work is subcontracted, it is detrimental to the project to allow unacceptable pipe work to continue. If the pipe work has to be dug-up and redone at a later date, many other trades will be adversely affected.

Nationwide Consulting, LLC can inspect every item of work on the project if necessary. From our experience, one can predict the final quality (or acceptability) of pipe work by how the pipe foremen organizes the work. If the transit is set-up, the backhoe always digging, trenches are straight, and the pipe fitters are working methodically, the pipe work will typically be successful. On the other hand, a disorganized foreman and crew that appear to start and stop and constantly change methods are headed for trouble. At Nationwide Consulting, LLC we are aware of how the underground pipe works progresses and we try to head-off quality problems early. This type of qualified and experienced supervision can save days or in some case weeks of time and labor in the long run.

It’s also important to have a basic understanding of the common pipe types. Most projects we see these days use High Density Polyethylene (HDPE) pipe. There are lots of variations of HDPE available, and we have worked with most of them. Sometimes concrete pipe still comes through as the best choice, due to its strength and durability. Corrugated metal pipe (CMP) may also be used in some site plans; we have worked with everything over the years at Nationwide Consulting, LLC.

The degree to which storm sewer or stormwater pipe must be water-tight is normally made clear in the project specifications. Sometimes, a bit of water leakage from storm sewer piping is acceptable (often a trade off for lower cost and easier installation) and other times the storm sewer piping must be water-tight under a low pressure.

The most important thing to remember about your site and its stormwater piping, is to have an experienced professional firm handle it cost effectively. At Nationwide Consulting, LLC, we are proud to say, we are that firm, we handle all aspects of developing your full construction project from site to finished structure, to spec efficiently, cost effectively and on time.

When it has to be done right, hit the Expert Button, call Nationwide Consulting, LLC

Call Nationwide Consulting, LLC today for a free consultation and you hit the expert button:

Call Nationwide Consulting, LLC today for a free consultation and you hit the expert button:

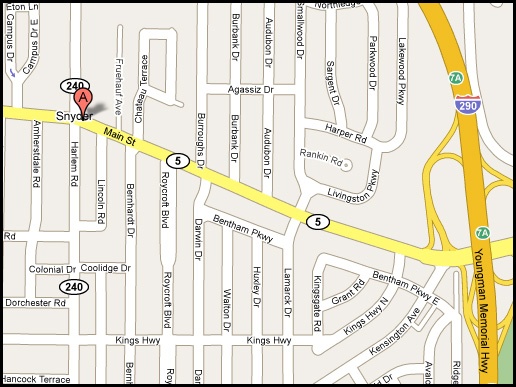

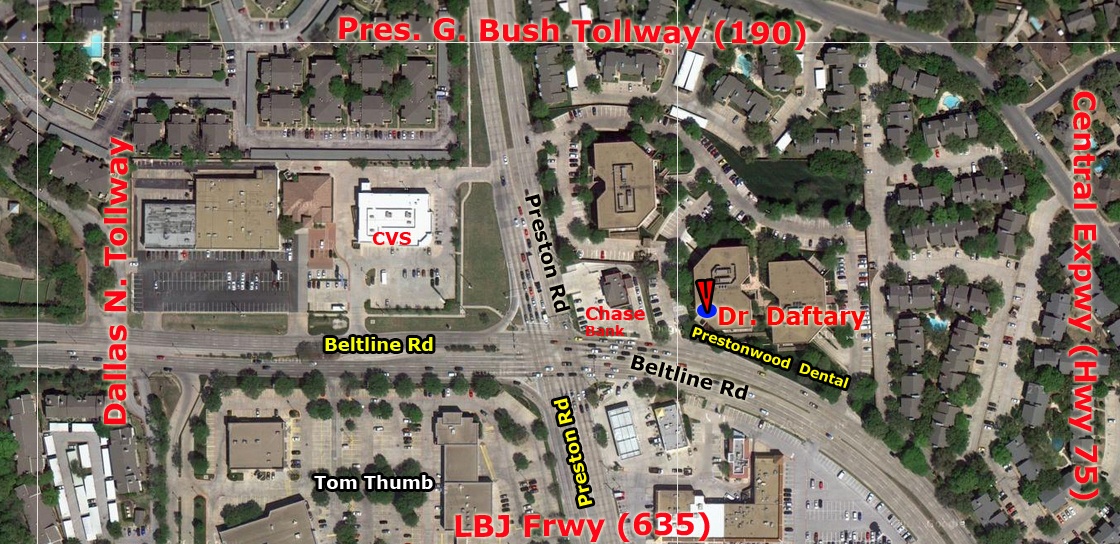

Nationwide Consulting, LLC

Robert E. Hanson

Principal Partner

410.336.4961